Ferrite

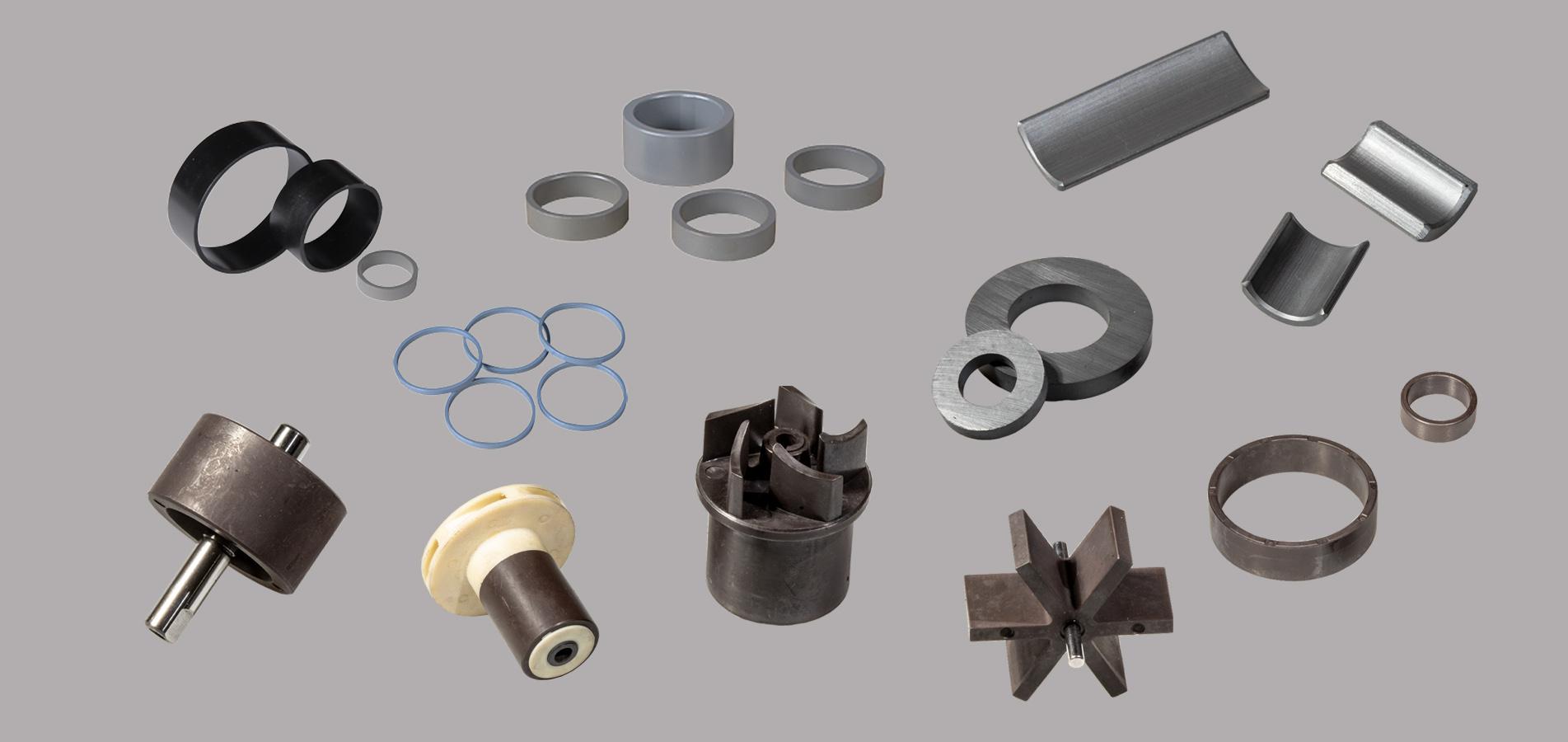

Ferrite magnets are low-cost, lightweight permanent magnets with moderate energy levels and relatively high coercive strength, capable of operating at temperatures up to 480°F. They offer excellent corrosion resistance, making them ideal for high-volume applications in manufacturing and consumer products. Ferrite magnets are available in two types: isotropic and anisotropic. Isotropic ferrite magnets have lower magnetic properties due to their nearly uniform magnetic behaviour in all directions, allowing them to be magnetized in multiple directions or multi-poles. Anisotropic ferrite magnets have better magnetic properties.

♦ Cost-effective solution for high-volume applications

♦ Medium strength performance

♦ High-temperature resistance

♦ Available in both isotropic and anisotropic grades

♦ Corrosion-resistant for durability

♦ Capable of withstanding high temperatures up to 300°C

♦ Cost-effective solution for low Br requirements, up to 4.2 MGOe

Classification and applications of ferrite magnets

Material Grades

Main Applications

Characteristics

Shapes

ZY10T

Strip magnet for sensor, disk, apparatus, household appliance, electric motor, medical device, sensor

Isotropic, material easy to multimagnetize by different direction, magnets with high precise dimension

Strip, cylinder, ring, U-shape

ZY20JZY20

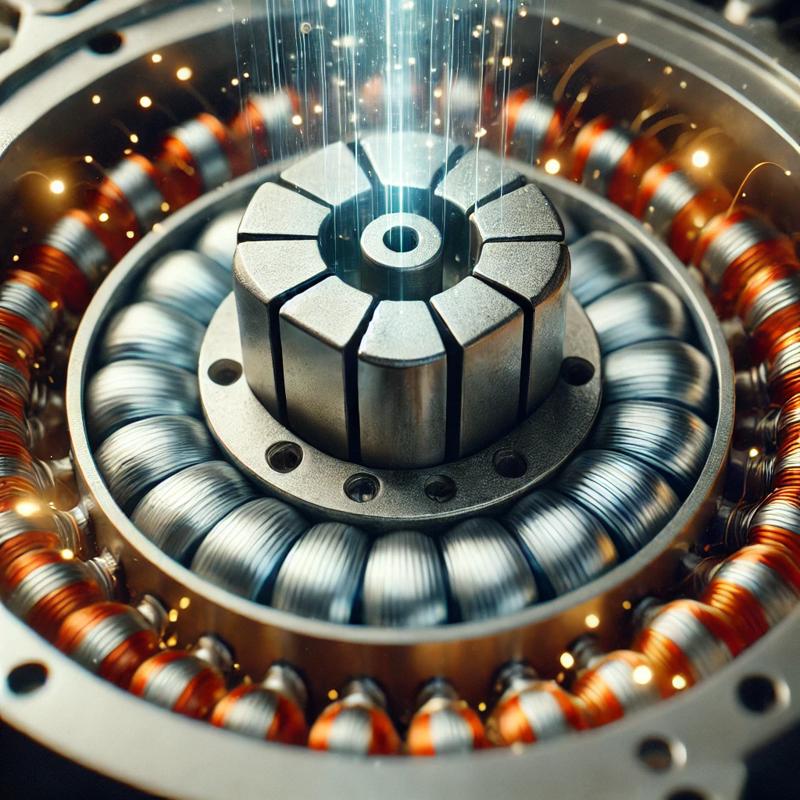

Electric motors for water and oil pump, and other micro-brushless motor rotor

Dry anisotropic products, multi-pole radial or full-eddy magnetic ring, high surface magnetic, stable performance characteristics

Cylinder, Ring

ZY25ZY30

All kinds of loudspeakers audio, electric-motor, medical device, sensor, receiver, pulling-system

High-density, high and stable performance

Ring, Cylinder, Block, Block and hole

ZY33HZY34HZY4036

Electric motors for electric tools, magnetic motor for motorcycle, electric motors for Auto. Applications such as wiper, power window, magnetic pulling devices, household appliance, medical treatment device, sensors, ABS motor, starter motors for motorcycle, plane motor

Moderate BR and Hcj, stable performance, strong capability in anti-demagnetization, extensive application

Segment, Block, Ring, Cylinder

ZY4129

High-quality loudspeakers, receivers, electric-motors for meters and instrument, magnetic adhesion, medical device, magnetic motor

High Br & sensitivity, stable, excellent quality, high flux density

Ring, Cylinder, Block

ZY4229

Microwave oven Magnetron, high-quality loudspeakers, receivers, electric-motors for office-equipment, apparatus and instrument, micro-motor

High Br and Hcb, high sensitivity stable, excellent quality, high flux density

Ring, Cylinder, Segment, Block

ZY3845ZY3850ZY4040ZY4350

Starter motors for automobile and for motorcycle, other motor for automobile, conditioning/ refrigerator compressor motor

High Hcb and Hcj, with strong capability in anti-demagnetization and aging, wide temperature range

Segment, Block

ZY4240ZY4040ZY4545

Starter motors for automobile, Electric motors for auto application such as ABS, blower , wiper and electric shift motor and adjustable Pedal motor, electric motors for household appliance, compressors of air-conditioners and etc.

higher Br and high flux density, with high power, stable performance, extensive application

Segment, Ring, Block

ZY4433ZY4646

Electric motors for oil pump and throttle of auto. as well as high -grade loudspeakers, meters, household appliance and office automation

Higher Br with high sensitivity applying for micro-sized high performance motors

Segment, Ring, Block

ZY4654ZY4748

Starter motors for automobile, compressors of air-conditioner and refrigerator, electric motors for auto appliance such as ABS, power window, sunroofs and oil pump

Higher Br and high flux, strong capability in anti-demagnetization, low temperature coefficient

segment, Block

English

English

08 March, 2025

08 March, 2025