Compression Bonded Neodymium Magnets offer exceptional versatility with multiple processing options, featuring strong mechanical properties and higher electrical resistivity than sintered magnets. Compression bonded neodymium magnets can be produced in complex shapes with precise geometric tolerances. Made from hard magnetic powder combined with a non-magnetic polymer or rubber binder, the powder can consist of materials like hard ferrite, alnico, or rare earth elements. Ideal for minimizing cogging torque in motors, compression bonded neodymium magnets are well-suited for high-volume applications. Their machinability makes them perfect for low-volume production as well, allowing for customized magnetizing patterns, including multipole or skewed poles. The epoxy binder in compression bonded neodymium magnets ensures strong resistance to industrial and automotive fluids and solvents, enhancing durability.

| ∇ Strong magnetic performance |

| ∇ Capable of achieving tight tolerances |

| ∇ Excellent mechanical strength |

| ∇ Resistant to corrosion and mild chemicals |

| ∇ Isotropic, allowing magnetization in any direction |

| ∇ Operating temperature range from -40˚C to 165˚C |

| Grade | Remanence | Intrinsic Coercivity | Magnetic Induction Coercivity | Max Magnetic Energy Product | Maximum Working Temperature | Recoil Permeability | Saturation Magnetizing Force | Density | Reversible Temp Coefficient | |||||

| Br | Hcj | Hcb | (BH) max | °C | μ rec | Hs | g/cm³ | %/°C | ||||||

| KGs | mT | KOe | KA/m | KOe | KA/m | MGOe | KJ/m³ | KOe | KA/m | |||||

| BNM-5 | 5.7-6.2 | 570-620 | 7.0-9.0 | 560-720 | 3.6-4.0 | 288-320 | 5.0-6.0 | 40-48 | 120-140 | 1.1-1.2 | ≥20 | ≥1600 | 5.8-6.2 | -0.1~-0.13 |

| BNM-6 | 5.8-6.3 | 580-630 | 8.0-10.0 | 640-800 | 4.0-4.7 | 322-376 | 6.0-7.0 | 48-56 | 120-140 | 1.1-1.2 | ≥20 | ≥1600 | 5.8-6.2 | -0.1~-0.13 |

| BNM-7 | 5.9-6.4 | 590-640 | 8.0-10.0 | 640-800 | 4.5-5.2 | 360-416 | 7.0-8.0 | 56-64 | 120-140 | 1.1-1.2 | ≥20 | ≥1600 | 5.8-6.2 | -0.1~-0.13 |

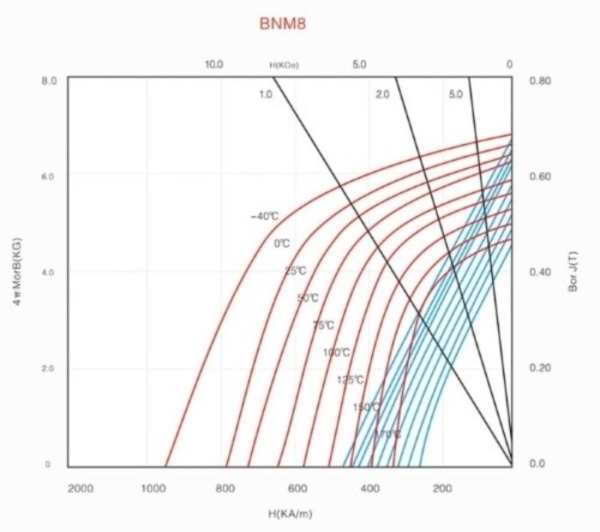

| BNM-8 | 6.2-6.7 | 620-670 | 8.5-10.0 | 680-800 | 5.0-5.8 | 400-464 | 8.0-9.0 | 64-72 | 120-140 | 1.1-1.2 | ≥20 | ≥1600 | 5.8-6.2 | -0.1~-0.13 |

| BNM-9 | 6.4-6.9 | 640-690 | 8.5-10.0 | 680-800 | 5.2-5.6 | 416-448 | 8.5-9.5 | 68-76 | 120-140 | 1.1-1.2 | ≥20 | ≥1600 | 5.8-6.2 | -0.1~-0.13 |

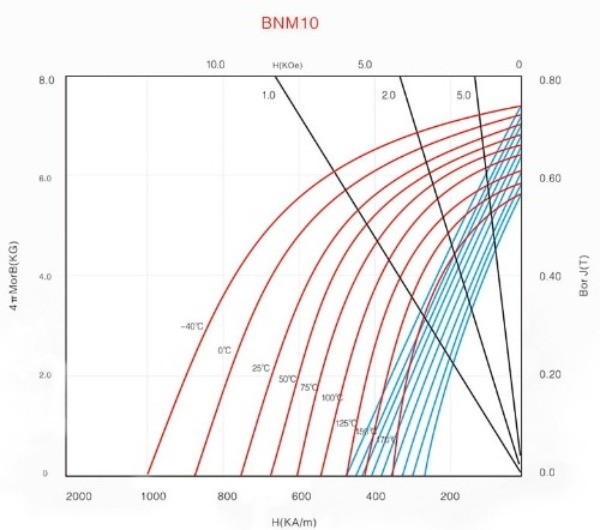

| BNM-10 | 6.7-7.2 | 670-720 | 8.5-10.0 | 680-800 | 5.2-6.0 | 416-480 | 9.0-10.0 | 72-80 | 120-140 | 1.1-1.2 | ≥20 | ≥1600 | 5.8-6.2 | -0.1~-0.13 |

| BNM-11 | 6.9-7.4 | 690-740 | 9.0-10.5 | 720-840 | 5.0-5.8 | 400-464 | 10.0-11.0 | 80-88 | 120-140 | 1.1-1.2 | ≥20 | ≥1600 | 5.8-6.2 | -0.1~-0.13 |

| BNM-12 | 7.4-7.6 | 740-760 | 9.0-10.5 | 720-840 | 5.7-6.4 | 456-512 | 11.0-12.0 | 88-96 | 120-140 | 1.1-1.2 | ≥20 | ≥1600 | 6.0-6.4 | -0.1~-0.13 |

| BNM-11L | 7.0-7.5 | 700-750 | 6.5-8.0 | 520-640 | 5.0-5.8 | 400-464 | 10.0-11.0 | 80-88 | 120-140 | 1.1-1.2 | ≥20 | ≥1600 | 5.8-6.2 | -0.1~-0.13 |

| BNM-12L | 7.5-8.0 | 750-800 | 6.5-8.0 | 520-640 | 5.4-6.2 | 432-496 | 10.5-11.5 | 84-92 | 120-140 | 1.1-1.2 | ≥20 | ≥1600 | 5.8-6.2 | -0.08~-0.13 |

| BNM-8SR | 6.2-6.7 | 620-670 | 11.0-14.0 | 880-1120 | 5.0-5.8 | 400-464 | 8.0-9.0 | 64-72 | 140-160 | 1.1-1.2 | ≥20 | ≥1600 | 5.8-6.2 | -0.1~-0.13 |

unit:mm

| Height Range | Height Tolerance | Parallelism | Rectangularity |

| ≤4 | 0.06 | 0.04 | 0.04 |

| 4-10 | 0.08 | 0.05 | 0.06 |

| 10-18 | 0.10 | 0.06 | 0.08 |

| 18-30 | 0.15 | 0.08 | 0.10 |

| 30-50 | 0.20 | 0.10 | 0.12 |

| >50 | 0.30 | 0.10 | 0.12 |

| Diameter Range | Diameter Tolerance | Circularity | Concentricity |

| ≤4 | 0.03 | 0.02 | 0.04 |

| 4-10 | 0.04 | 0.02 | 0.05 |

| 10-18 | 0.06 | 0.03 | 0.05 |

| 18-30 | 0.08 | 0.04 | 0.06 |

| 30-50 | 0.10 | 0.05 | 0.06 |

| 50-80 | 0.10 | 0.06 | 0.08 |

| >80 | 0.12 | 0.06 | 0.08 |

Demagnetization Curve

The performance of compression bonded neodymium magnets within a magnetic circuit is influenced by various factors, including its performance coefficient and the operating environment. Fully magnetized permanent magnets have magnetic domains aligned in a specific orientation. However, under certain conditions, some of these domains can shift out of alignment, causing the magnet to lose part or all of its magnetic field.

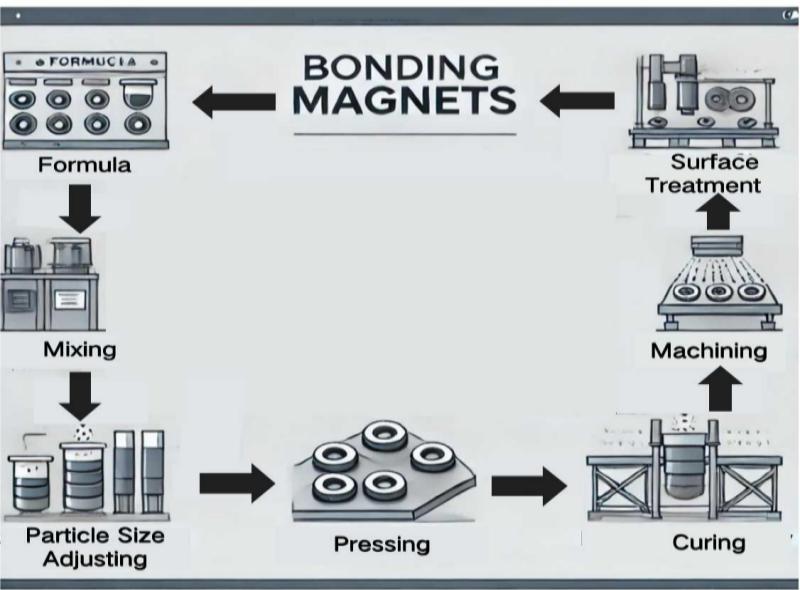

Process Flow