Why Permanent Magnets Are Key To Innovation

May 07, 2025

Permanent magnets play a pivotal role in shaping modern innovation. Their unparalleled magnetic properties enable groundbreaking advancements in energy efficiency and cutting-edge technologies. As a permanent magnets and magnetic assemblies manufacturer, Zoyn leads the charge in delivering innovative solutions that power industries worldwide.

The demand for magnets continues to rise due to their critical role in renewable energy systems and electromobility. For instance:

NdFeB magnets, the cornerstone of renewable energy technologies, account for 23% of all rare earth elements produced globally.

Their application in wind turbines and electric vehicles underscores their importance in reducing carbon footprints.

Recycling discarded NdFeB magnets has become a priority to address supply risks and promote sustainability.

Research highlights the social implications of these materials, emphasizing the need for sustainable sourcing to build trust in energy industries. By prioritizing eco-friendly practices, companies like Zoyn contribute to a greener future while driving innovation.

Explore how magnets power the technologies shaping our world, from renewable energy to advanced medical devices. Zoyn’s commitment ensures these innovations remain at the forefront of global progress.

Key Takeaways

Permanent magnets are important for clean energy, making wind turbines and electric cars work better.

Recycling rare earth magnets is key to saving resources and protecting the environment.

New magnetic materials improve how things work, helping healthcare and robots get better.

More people need permanent magnets because they save energy and help clean technology grow.

Making magnets locally can make supplies stronger and help the planet.

Unique Properties of Permanent Magnets

Image Source: pexels

Magnetic Properties That Drive Innovation

Permanent magnets possess unique magnetic properties that make them indispensable in modern technology. Their ability to generate a persistent magnetic field without external power sets them apart from other materials. This characteristic enables their use in applications where reliability and efficiency are paramount. For instance, sintered neodymium magnets, known for their exceptional strength, are widely used in electric vehicles and renewable energy systems. These magnets deliver high energy density, allowing for compact designs in advanced devices.

Recent advancements in magnetic materials have further enhanced their performance. Researchers at the Korea Institute of Materials Science (KIMS) developed a two-step grain boundary diffusion process. This technique improves coercivity while reducing reliance on heavy rare earth metals. The resulting magnets achieve coercivity grades between 45SH and 40UH, making them suitable for high-performance power electronics like drones and robotics. These innovations not only improve efficiency but also address global concerns about resource independence and supply security.

Moreover, studies on the magnetocaloric effect in nanostructured magnetic alloys highlight their potential in magnetic refrigeration. This technology offers a sustainable alternative to traditional cooling systems, reducing energy consumption and environmental impact. The demand for such innovations continues to grow as industries seek eco-friendly solutions.

Critical Role in Advanced Technologies

Permanent magnets play a critical role in driving advancements across various industries. Their applications extend beyond traditional uses, powering cutting-edge technologies that shape our future. For example, iron-based superconducting permanent magnets outperform previous models in generating high magnetic field strengths. This breakthrough has practical applications in industries requiring precision and reliability, such as medical imaging and particle accelerators.

In the realm of renewable energy, magnets are essential components of wind turbines and electric vehicle motors. NdFeB magnets, derived from rare earth metals, are particularly valuable due to their high energy efficiency. These magnets enable the production of lightweight, compact motors that reduce energy consumption while maintaining performance. As the demand for sustainable energy solutions rises, the role of magnets in these technologies becomes even more significant.

A comparative analysis of electromagnetic harvesters reveals the superior performance of permanent magnets in innovation contexts. Their ability to convert mechanical energy into electrical energy efficiently makes them ideal for energy harvesting applications. This capability supports the development of self-powered devices, reducing reliance on external power sources and enhancing sustainability.

The versatility of permanent magnets ensures their integration into diverse fields, from consumer electronics to aerospace engineering. Their unique properties and adaptability make them a cornerstone of technological progress, meeting the growing demand for efficient and reliable solutions.

Applications in Modern Technology

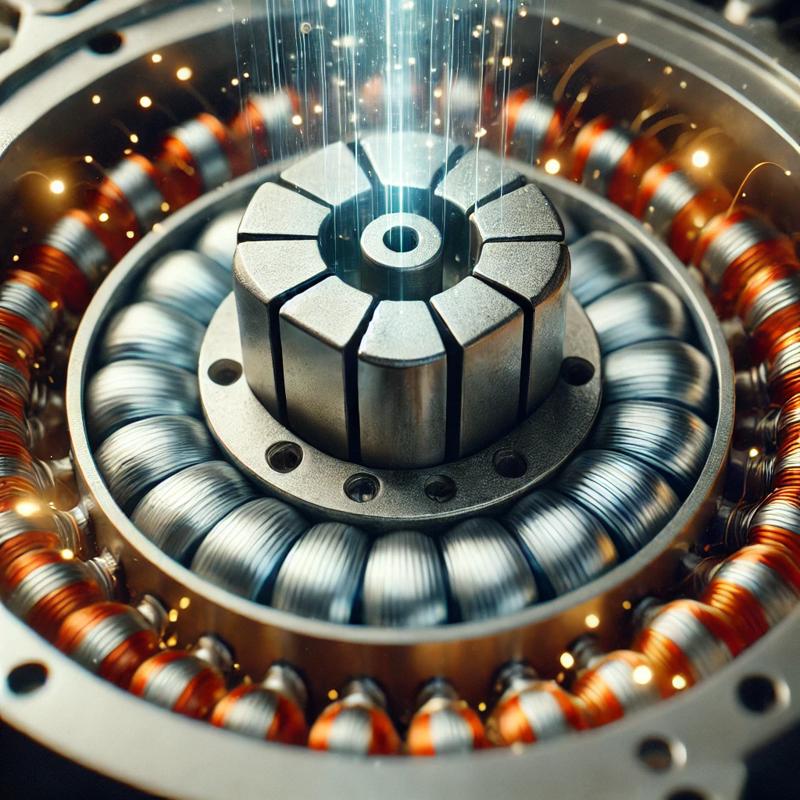

Image Source: unsplash

Renewable Energy Systems

Permanent magnets are revolutionizing renewable energy systems by enhancing efficiency and reliability. Their role in wind turbines is particularly noteworthy. These magnets generate a strong and constant magnetic field, which improves generator efficiency and reduces maintenance needs. The compact design enabled by their high magnetic strength allows for smaller, lighter turbines, making them ideal for both on-grid and off-grid applications. Recent advancements in wind energy systems have focused on improving stability and autonomy, further solidifying the importance of magnets in renewables integration.

The demand for renewable energy technologies continues to rise due to global environmental challenges. Permanent magnets, especially those made from rare earth metals, are integral to energy conversion systems like wind and solar power. Market research reports highlight this trend, showing a significant increase in the use of magnets in renewable energy projects. For example:

High efficiency enhances turbine performance and energy conversion rates.

Low maintenance reduces wear and tear, minimizing operational costs.

Compact designs allow for reduced size and weight, making installations more feasible in diverse environments.

A case study on wind energy projects demonstrates the effectiveness of permanent magnets in energy systems. The data reveals their ability to optimize energy output while reducing maintenance requirements, making them indispensable in the transition to sustainable energy solutions.

Electronics and Medical Devices

Magnets are the backbone of modern electronics and medical devices. In consumer electronics, they are essential components in smartphones, motors, and refrigerators. The growing demand for these devices has fueled the expansion of the electronics industry, with permanent magnets playing a critical role in meeting this demand. Rare earth metals like neodymium are widely used in these applications due to their exceptional magnetic properties, enabling compact and efficient designs.

In the medical field, magnets are transforming healthcare technologies. Magnetic resonance imaging (MRI) machines rely on high-performance magnets to produce detailed images of the human body. These magnets ensure precision and reliability, which are crucial for accurate diagnoses. Additionally, advancements in magnetocaloric materials are paving the way for magnetic refrigeration systems in medical facilities, offering energy-efficient cooling solutions.

The electric mobility sector also benefits from the integration of magnets. Electric vehicles, which saw a 35% increase in registrations in 2023, depend on rare earth magnets for their motors and battery systems. These magnets enable lightweight and compact designs, improving vehicle efficiency and reducing energy consumption. As the demand for electric vehicles grows, the role of magnets in this industry becomes even more significant.

Industrial Advancements

Permanent magnets are driving innovation in industrial machinery and automation. Their applications range from robotics to HVAC systems, where they enhance performance and efficiency. The Permanent Magnet Synchronous Motor (PMSM) market, valued at $27.01 billion in 2024, is projected to grow at a compound annual growth rate (CAGR) of 8.5%. This growth reflects the increasing use of magnets in industrial automation and electric power systems.

Rare earth metals are at the core of these advancements. They enable the production of high-performance magnets that deliver exceptional strength and reliability. For instance, PMSMs are widely used in industrial machinery, electric vehicles, and wind turbines. These motors offer superior energy efficiency and durability, making them ideal for demanding applications.

Market research reports indicate that the global permanent magnets market, valued at USD 24.36 billion in 2024, is expected to reach USD 51.78 billion by 2033. This growth underscores the expanding role of magnets in various sectors, including automotive, electronics, healthcare, and renewable energy. The demand for these materials continues to rise as industries seek innovative solutions to improve efficiency and sustainability.

Magnets are also transforming the automation landscape. Their ability to convert mechanical energy into electrical energy efficiently supports the development of self-powered devices. This capability reduces reliance on external power sources, enhancing sustainability and reliability in industrial applications.

Sustainability and Climate Change

Reducing Energy Consumption

Permanent magnets play a pivotal role in reducing energy consumption across industries. Their ability to generate strong and consistent magnetic fields without external power makes them indispensable in clean energy technologies. For instance, electric motors and generators equipped with rare earth magnets operate with higher efficiency, minimizing energy losses. This efficiency directly supports the clean energy transition by lowering the overall energy demand in critical applications like electric vehicles and wind turbines.

Governments and environmental agencies have recognized the importance of magnets in energy efficiency. According to a roadmap for sustainable energy innovations:

Year

Description

2025–2027

Design, build, and validate a proof-of-concept prototype electric machine with reduced rare-earth magnets.

2027–2030

Expand to other industries by advancing magnet and conductor technologies.

2030–Beyond

Integrate into production lines for industry adoption.

These milestones highlight the growing demand for advanced magnetic solutions to drive the energy transition. By improving energy efficiency, magnets reduce environmental impacts and contribute to global efforts to combat climate change.

Enabling Green Technologies

Magnets are at the heart of green technologies, enabling innovations that address climate change. Rare earth metals, essential for producing High-Performance Neodymium Magnet, are integral to clean energy technologies like wind turbines and solar power systems. Their compact size and high energy density allow for lightweight designs, making installations more feasible in diverse environments.

Recycling rare earth magnets further enhances sustainability. Companies like Apple have committed to using 100% recycled rare earth metals in their devices, aiming for carbon neutrality by 2030. This approach not only reduces environmental harm but also ensures a steady supply of materials for the growing demand in green technologies. Collaborative efforts among stakeholders have also fostered sustainable business models, ensuring the viability of these innovations in the market.

The clean energy transition relies heavily on magnets to power technologies that reduce carbon footprints. From electric vehicles to renewable energy systems, these materials are indispensable in creating a sustainable future. As industries continue to innovate, the role of magnets in addressing climate challenges will only grow.

Future Potential of Permanent Magnets

Emerging Technologies

The future of permanent magnets lies in their ability to power emerging technologies. I see a growing focus on domestic rare earth magnet production, which enhances supply chain stability and reduces reliance on imports. This shift is critical as industries like electric vehicles (EVs) and renewable energy continue to expand. Permanent magnets are essential for efficient electric motors in EVs, improving performance and energy efficiency. Similarly, their role in wind turbines highlights their importance in global sustainability initiatives.

Key trends driving growth:

Increasing investments in local magnet production facilities.

Rising demand for EVs and renewable energy systems.

Advancements in recycling technologies for rare earth elements.

Early-stage projects like Mkango Resources Limited are paving the way for sustainable magnet production. This initiative supports critical mineral supply chains while revitalizing NdFeB magnet manufacturing in the U.S. Additionally, companies like Ionic Technologies are innovating extraction processes to recover rare earth elements from recycled magnets. These advancements not only ensure a steady supply but also promote eco-friendly practices.

The potential of permanent magnets extends beyond traditional applications. For instance, their integration into energy harvesting devices enables self-powered systems, reducing dependency on external power sources. This capability is crucial for developing autonomous technologies in sectors like robotics and IoT.

Innovations in Magnetic Solutions

Innovations in magnetic solutions are shaping the future of technology. I find advancements in 2D magnetism particularly exciting. These ultra-thin magnets offer unique features like quantum confinement and mechanical flexibility, making them ideal for quantum devices and biomedical applications. Their use in non-volatile memory and spin-based logic devices could revolutionize data storage and computing.

Topic

Description

2D Magnetism

Enables ultracompact devices and quantum computing through enhanced sensitivity.

Heat-Assisted Magnetic Recording (HAMR)

Improves data storage density by using thermal assistance during writing.

HAMR technology exemplifies how magnetic innovations enhance precision and efficiency. By temporarily heating the recording medium, this method achieves higher-density data storage, meeting the growing demand for advanced hard disk drives.

The renewable energy sector also benefits from novel magnetic solutions. High-performance magnets in wind turbines and solar power systems optimize energy conversion, supporting the clean energy transition. As industries invest in sustainable technologies, the demand for innovative magnetic materials will only grow.

Permanent magnets are poised to redefine technological boundaries. From quantum computing to green energy, their versatility ensures they remain at the forefront of innovation. By embracing these advancements, we can unlock new possibilities for a sustainable and technologically advanced future.

Permanent magnets are the backbone of modern innovation, driving advancements in sustainability and technology. Their unique properties enable critical applications in renewable energy, electric vehicles, and consumer electronics. For instance, the rapid adoption of EVs and the expansion of wind energy highlight their transformative role in addressing global challenges like climate change.

The global magnet market is projected to grow from USD 38.61 billion in 2024 to USD 64.74 billion by 2035, fueled by the demand for neodymium iron boron magnets in EV motors and renewable energy systems.

Category

Evidence

Opportunity

Renewable energy expansion, especially wind power, relies on magnets.

Driver

EV adoption accelerates magnet market growth by enhancing motor performance.

As companies like Zoyn continue to innovate, the future of permanent magnets looks promising. Their contributions to green technologies and energy efficiency will shape a sustainable world, ensuring we meet the challenges of our changing climate. Explore how Zoyn’s high-performance magnets can power the next generation of solutions.

Contact us:

WhatsApp: +86 15888988057

Read More