Bonded Neodymium Block Magnets: High-Performance Magnetic Solutions for Versatile Applications

Bonded neodymium block magnets are compact, lightweight, and highly customizable magnetic components designed to deliver powerful performance in a wide range of applications. Manufactured using a bonding process that combines neodymium magnetic powder with polymer binders, bonded neodymium block magnets provide exceptional magnetic strength with superior precision and durability. Their rectangular or square shape makes them ideal for use in motors, sensors, actuators, and various industrial assemblies.

At Zoyn, we specialize in producing high-quality bonded neodymium block magnets tailored to meet the specific needs of industries such as automotive, electronics, renewable energy, and industrial automation. With customizable sizes, magnetic properties, and coatings, our magnets deliver exceptional performance, reliability, and cost efficiency for even the most demanding applications.

Key Features of Bonded Neodymium Block Magnets

1. Exceptional Magnetic Strength

Bonded neodymium block magnets deliver high magnetic performance, making it suitable for advanced industrial and technical applications.

2. Customizable Dimensions

Available in various sizes and thicknesses to fit seamlessly into specific designs and assemblies.

3. Versatile Magnetization Options

Bonded neodymium block magnets can be magnetized in axial, radial, or multipole configurations, allowing for tailored solutions to meet specific application requirements.

4. Lightweight and Durable

The bonded structure reduces weight while maintaining mechanical strength and durability, ideal for compact and lightweight applications.

5. Corrosion Resistance

Naturally resistant to rust and moisture, with optional protective coatings (such as epoxy or nickel) for enhanced durability in harsh environments.

6. Cost-Effective Manufacturing

The bonding process allows for economical production of complex shapes and high-volume orders, making it ideal for scalable applications.

7. High Precision and Tight Tolerances

Enables accurate integration into assemblies, ensuring consistent and reliable performance in demanding applications.

8. Temperature Resistance

Specialized grades are available for high-temperature environments, ensuring stability and reliability in extreme conditions.

9. Versatile Applications

Bonded neodymium block magnets are ideal for use in motors, actuators, sensors, industrial automation, and renewable energy systems.

| Grade | Remanence | Intrinsic Coercivity | Magnetic Induction Coercivity | Max Magnetic Energy Product | Maximum Working Temperature | Recoil Permeability | Saturation Magnetizing Force | Density | Reversible Temp Coefficient | |||||

| Br | Hcj | Hcb | (BH) max | °C | μ rec | Hs | g/cm³ | %/°C | ||||||

| KGs | mT | KOe | KA/m | KOe | KA/m | MGOe | KJ/m³ | KOe | KA/m | |||||

| BNM-5 | 5.7-6.2 | 570-620 | 7.0-9.0 | 560-720 | 3.6-4.0 | 288-320 | 5.0-6.0 | 40-48 | 120-140 | 1.1-1.2 | ≥20 | ≥1600 | 5.8-6.2 | -0.1~-0.13 |

| BNM-6 | 5.8-6.3 | 580-630 | 8.0-10.0 | 640-800 | 4.0-4.7 | 322-376 | 6.0-7.0 | 48-56 | 120-140 | 1.1-1.2 | ≥20 | ≥1600 | 5.8-6.2 | -0.1~-0.13 |

| BNM-7 | 5.9-6.4 | 590-640 | 8.0-10.0 | 640-800 | 4.5-5.2 | 360-416 | 7.0-8.0 | 56-64 | 120-140 | 1.1-1.2 | ≥20 | ≥1600 | 5.8-6.2 | -0.1~-0.13 |

| BNM-8 | 6.2-6.7 | 620-670 | 8.5-10.0 | 680-800 | 5.0-5.8 | 400-464 | 8.0-9.0 | 64-72 | 120-140 | 1.1-1.2 | ≥20 | ≥1600 | 5.8-6.2 | -0.1~-0.13 |

| BNM-9 | 6.4-6.9 | 640-690 | 8.5-10.0 | 680-800 | 5.2-5.6 | 416-448 | 8.5-9.5 | 68-76 | 120-140 | 1.1-1.2 | ≥20 | ≥1600 | 5.8-6.2 | -0.1~-0.13 |

| BNM-10 | 6.7-7.2 | 670-720 | 8.5-10.0 | 680-800 | 5.2-6.0 | 416-480 | 9.0-10.0 | 72-80 | 120-140 | 1.1-1.2 | ≥20 | ≥1600 | 5.8-6.2 | -0.1~-0.13 |

| BNM-11 | 6.9-7.4 | 690-740 | 9.0-10.5 | 720-840 | 5.0-5.8 | 400-464 | 10.0-11.0 | 80-88 | 120-140 | 1.1-1.2 | ≥20 | ≥1600 | 5.8-6.2 | -0.1~-0.13 |

| BNM-12 | 7.4-7.6 | 740-760 | 9.0-10.5 | 720-840 | 5.7-6.4 | 456-512 | 11.0-12.0 | 88-96 | 120-140 | 1.1-1.2 | ≥20 | ≥1600 | 6.0-6.4 | -0.1~-0.13 |

| BNM-11L | 7.0-7.5 | 700-750 | 6.5-8.0 | 520-640 | 5.0-5.8 | 400-464 | 10.0-11.0 | 80-88 | 120-140 | 1.1-1.2 | ≥20 | ≥1600 | 5.8-6.2 | -0.1~-0.13 |

| BNM-12L | 7.5-8.0 | 750-800 | 6.5-8.0 | 520-640 | 5.4-6.2 | 432-496 | 10.5-11.5 | 84-92 | 120-140 | 1.1-1.2 | ≥20 | ≥1600 | 5.8-6.2 | -0.08~-0.13 |

| BNM-8SR | 6.2-6.7 | 620-670 | 11.0-14.0 | 880-1120 | 5.0-5.8 | 400-464 | 8.0-9.0 | 64-72 | 140-160 | 1.1-1.2 | ≥20 | ≥1600 | 5.8-6.2 | -0.1~-0.13 |

unit:mm

| Height Range | Height Tolerance | Parallelism | Rectangularity |

| ≤4 | 0.06 | 0.04 | 0.04 |

| 4-10 | 0.08 | 0.05 | 0.06 |

| 10-18 | 0.10 | 0.06 | 0.08 |

| 18-30 | 0.15 | 0.08 | 0.10 |

| 30-50 | 0.20 | 0.10 | 0.12 |

| >50 | 0.30 | 0.10 | 0.12 |

| Diameter Range | Diameter Tolerance | Circularity | Concentricity |

| ≤4 | 0.03 | 0.02 | 0.04 |

| 4-10 | 0.04 | 0.02 | 0.05 |

| 10-18 | 0.06 | 0.03 | 0.05 |

| 18-30 | 0.08 | 0.04 | 0.06 |

| 30-50 | 0.10 | 0.05 | 0.06 |

| 50-80 | 0.10 | 0.06 | 0.08 |

| >80 | 0.12 | 0.06 | 0.08 |

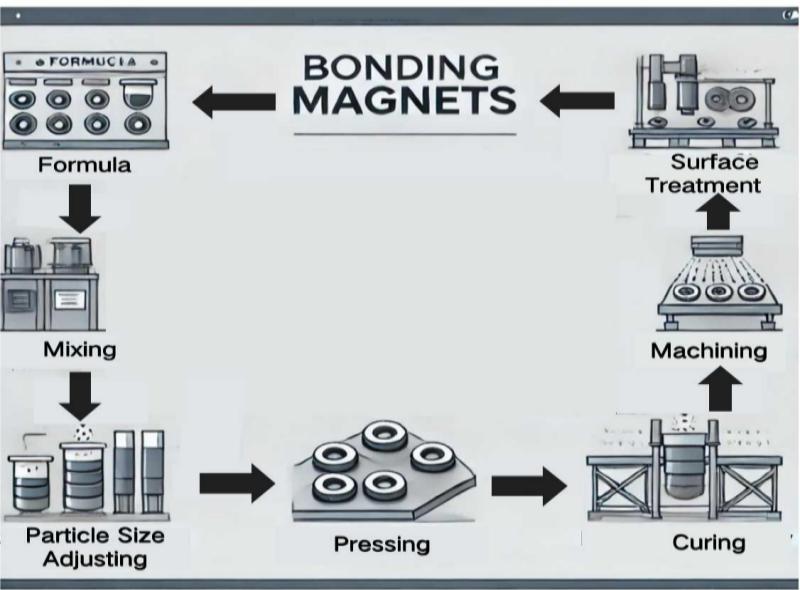

Process Flow