Custom Solution

Our team delivers tailored magnetic solutions across industries such as automotive, electronics, medical devices, renewable energy, and industrial manufacturing. With deep expertise in magnet technology, we address sector-specific challenges, enabling high-performance outcomes in applications like EV motors, precision sensors, medical imaging, renewable energy systems, and industrial automation. Our customized approach ensures innovative, efficient, and reliable solutions for every industry need.

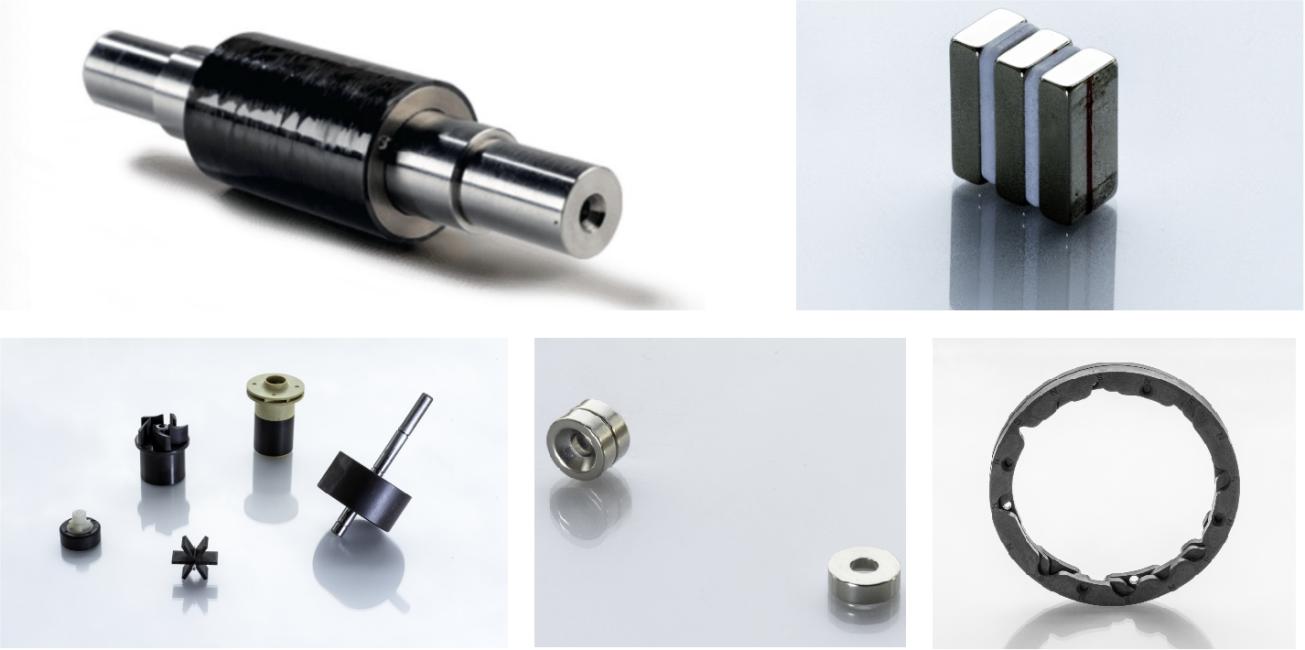

Types of Custom Magnets We Offer

We provide various customization options to meet your unique needs, including:

1. Consultation and Requirement Gathering: Our process starts with an in-depth consultation to fully understand your unique needs, application requirements, and technical specifications. Whether you’re looking for a standard product or a custom solution, our team takes the time to assess all factors, including operating conditions, environmental factors, and performance goals. This ensures that the final design aligns perfectly with your expectations and project requirements.

2. Design and Engineering Support: Our engineering team works closely with you to develop magnet designs that meet precise performance criteria. From material selection and shape optimization to magnetic strength and thermal stability, we combine technical expertise with innovative thinking. Advanced simulation tools and modeling software allow us to visualize and refine designs, ensuring optimal performance and functionality for your specific application.

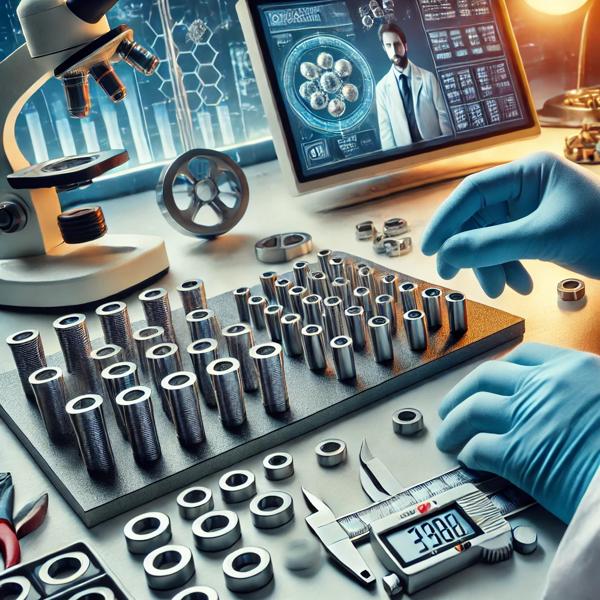

3. Prototyping and Testing: To ensure the solution meets real-world demands, we produce high-quality prototype samples that undergo thorough testing in your intended application conditions. This step allows us to validate designs, identify potential improvements, and make adjustments if necessary, ensuring the final product meets both quality standards and performance expectations.

4. Production and Quality Control: Our advanced manufacturing facilities are equipped to handle production with precision and efficiency. We utilize state-of-the-art techniques to create magnets and assemblies that meet exact specifications, whether for small custom orders or large-scale manufacturing. Throughout the process, rigorous quality control measures are implemented at every stage, including material testing, dimensional inspections, and magnetic property verification, ensuring consistent quality and reliability.

5. Delivery and After-Sales Support: Once production is complete, our logistics team ensures timely and efficient delivery, coordinating shipments to meet your schedules. Our commitment doesn’t end there—our dedicated after-sales support team remains available to address any questions, provide technical assistance, and ensure your satisfaction with the product.

Here’s a closer look at some of the industries that benefit from our custom magnet solutions:

Would you like to expand on any particular section or add unique features like downloadable technical datasheets, a FAQ, or a video explaining your custom magnet process? Let me know if any of these ideas resonate!