Ferrite Block Magnets, also known as ceramic block magnets, are a versatile and economical choice for various industrial, automotive, and consumer applications. With their rectangular or square shape, ferrite block magnets provide excellent performance and durability, making them ideal for motors, sensors, and magnetic assemblies. Manufactured from iron oxide and ceramic materials, ferrite block magnets are highly resistant to corrosion and demagnetization, ensuring reliable, long-term operation in demanding environments.

At ZOYN, we offer high-quality ferrite block magnets that can be customized to meet your specific size, strength, and application requirements. Whether used in motors, separators, or renewable energy systems, our ferrite block magnets deliver consistent performance and exceptional value, making them a preferred choice for a wide range of industries.

1. Cost-Effective

Ferrite magnets are among the most affordable magnetic materials, making them ideal for mass production and budget-conscious projects.

2. Durable and Long-Lasting

Ferrite block magnets are highly resistant to rust, wear, and chemicals, ensuring dependable performance over time, even in harsh environments.

3. Thermal Stability

These magnets operate effectively in a wide temperature range, typically from -40°C to 250°C, making them suitable for applications requiring high thermal resistance.

4. Magnetic Stability

With high coercivity and resistance to demagnetization, ferrite block magnets maintain their magnetic properties under mechanical stress, exposure to external magnetic fields, or temperature changes.

5. Customizable Design

Ferrite block magnets can be customized in size, thickness, and strength to suit specific application requirements, ensuring seamless integration into your products.

6. Environmentally Friendly

Made from non-toxic, abundant raw materials, ferrite magnets are an eco-friendly choice for sustainable manufacturing.

Magnetic & Physical Properties

Remark: C//: parallel to akle, C⊥:perpendicular to axle; ( ): SI unit system, [ ]: CGSM unit system

| Material Grade | ZY10T | ZY30 | ZY33H | ZY34H | ZY3845 | ZY3850 | ZY4036 | ZY4040 | ZY4129 | ZY4240 | ZY4433 | ZY4350 | ZY4545 | ZY4654 | ZY4748 | |

| Composition | SrO · 6Fe2O3 BaO · 6Fe2O3 | SrO · 6Fe2O3 | SrO · 6Fe2O3 | SrO · 6Fe2O3 | SrO · 6Fe2O3 | SrO · 6Fe2O3 | SrO · 6Fe2O3 | SrO · 6Fe2O3 | SrO · 6Fe2O3 | SrO · 6Fe2O3 | SrO · 6Fe2O3 | SrO · 6Fe2O3 | SrO · 6Fe2O3 | SrO · 6Fe2O3 | SrO · 6Fe2O3 | |

|

Br Residual Flux Density |

(mT) | 210~240 | 390~410 | 390~410 | 370~390 | 370~390 | 370~390 | 395~415 | 390~410 | 400~420 | 410~430 | 430~450 | 420~440 | 440~460 | 450~470 | 460~480 |

| [Gs] | 2100~2400 | 3900~4100 | 3900~4100 | 3700~3900 | 3700~3900 | 3700~3900 | 3950~4150 | 3900~4100 | 4000~4200 | 4100~4300 | 4300~4500 | 4200~4400 | 4400~4600 | 4500~4700 | 4600~4800 | |

|

Hcb Coercive Force |

(kA/m) | 127~159 | 175~207 | 239~271 | 263~291 | 263~299 | 279~303 | 263~291 | 271~295 | 215~239 | 283~307 | 247~271 | 291~326 | 318~350 | 330~360 | 328~352 |

| [Oe] | 1600~2000 | 2200~2600 | 3000~3400 | 3300~3650 | 3300~3750 | 3500~3800 | 3300~3650 | 3400~3700 | 2700~3000 | 3550~3850 | 3100~3400 | 3700~4100 | 4000~4400 | 4150~4450 | 4150~4400 | |

|

Hcj Intrinsic Coercive Force |

(kA/m) | 211~279 | 179~211 | 243~275 | 307~330 | 342~378 | 382~406 | 279~303 | 307~326 | 219~243 | 307~330 | 251~275 | 386~410 | 347~370 | 415~445 | 368~392 |

| [Oe] | 2650~3500 | 2250~2650 | 3050~3450 | 3850~4150 | 4300~4750 | 4800~5100 | 3500~3800 | 3850~4100 | 2750~3050 | 3850~4150 | 3150~3450 | 4850~5150 | 4350~4650 | 5250~5550 | 4650~4950 | |

| (BH)max Max. Energy Product |

(kJ/m³) | 6.4~9.5 | 27.1~31.2 | 27.1~31.2 | 24.7~28.7 | 25.5~28.7 | 25.5~28.7 | 28.7~31.8 | 29.6~32.8 | 29.6~32.8 | 31.8~35.2 | 35.2~38.4 | 33.4~36.6 | 36.6~39.8 | 39.8~43.0 | 41.5~44.7 |

| [MGOe] | 0.8~1.2 | 3.4~3.9 | 3.4~3.9 | 3.1~3.6 | 3.2~3.6 | 3.2~3.6 | 3.6~4.0 | 3.7~4.1 | 3.7~4.1 | 4.0~4.4 | 4.4~4.8 | 4.2~4.6 | 4.6~5.0 | 5.0~5.4 | 5.2~5.6 | |

|

µec Relative Permeability |

1.1~1.2 | 1.05~1.1 | 1.05~1.1 | 1.05~1.1 | 1.05~1.1 | 1.05~1.1 | 1.05~1.1 | 1.05~1.1 | 1.05~1.1 | 1.05~1.1 | 1.05~1.1 | 1.05~1.1 | 1.05~1.1 | 1.05~1.1 | 1.05~1.1 | |

| rBr/Br/rT[%/°C] | -0.18 | -0.18 | -0.18 | -0.18 | -0.18 | -0.18 | -0.18 | -0.18 | -0.18 | -0.18 | -0.18 | -0.18 | -0.18 | -0.18 | -0.18 | |

|

(K) Curie Temperature |

733 | 733 | 733 | 733 | 733 | 733 | 733 | 733 | 733 | 733 | 733 | 723 | 723 | 723 | 723 | |

| Tc (°C) | 460 | 460 | 460 | 460 | 460 | 460 | 460 | 460 | 460 | 460 | 460 | 450 | 450 | 450 | 450 | |

|

rL/L/rT Thermal Coeffient of Expansion |

C//*(1/K)[1/°C] | (10~16)*10-6 | (10~16)*10-6 | (10~16)*10-6 | (10~16)*10-6 | (10~16)*10-6 | (10~16)*10-6 | (10~16)*10-6 | (10~16)*10-6 | (10~16)*10-6 | (10~16)*10-6 | (10~16)*10-6 | (10~16)*10-6 | (10~16)*10-6 | (10~16)*10-6 | (10~16)*10-6 |

| C⊥*(1/K)[1/°C] | 10.0*10-6 | 10.0*10-6 | 10.0*10-6 | 10.0*10-6 | 10.0*10-6 | 10.0*10-6 | 10.0*10-6 | 10.0*10-6 | 10.0*10-6 | 10.0*10-6 | 10.0*10-6 | 10.0*10-6 | 10.0*10-6 | 10.0*10-6 | 10.0*10-6 | |

| Density | (kg/m³) | (4.70~4.90)*103 | (4.80~5.00)*103 | (4.90~5.00)*103 | (4.80~5.00)*103 | (4.80~5.00)*103 | (4.80~5.00)*103 | (4.90~5.00)*103 | (4.90~5.00)*103 | (4.90~5.00)*103 | (4.90~5.00)*103 | (4.90~5.00)*103 | (4.90~5.10)*103 | (4.90~5.10)*103 | (4.90~5.10)*103 | (4.90~5.10)*103 |

| [g/cm³] | 4.70~4.90 | 4.80~5.00 | 4.90~5.00 | 4.80~5.00 | 4.80~5.00 | 4.80~5.00 | 4.90~5.00 | 4.90~5.00 | 4.90~5.00 | 4.90~5.00 | 4.90~5.00 | 4.90~5.10 | 4.90~5.10 | 4.90~5.10 | 4.90~5.10 | |

| Anti-Bending Strength | (N/m²) | (0.5~0.9)*108 | (0.5~0.9)*108 | (0.5~0.9)*108 | (0.5~0.9)*108 | (0.5~0.9)*108 | (0.5~0.9)*108 | (0.5~0.9)*108 | (0.5~0.9)*108 | (0.5~0.9)*108 | (0.5~0.9)*108 | (0.5~0.9)*108 | (0.5~0.9)*108 | (0.5~0.9)*108 | (0.5~0.9)*108 | (0.5~0.9)*108 |

| [kgf/mm²] | 5~9 | 5~9 | 5~9 | 5~9 | 5~9 | 5~9 | 5~9 | 5~9 | 5~9 | 5~9 | 5~9 | 5~9 | 5~9 | 5~9 | 5~9 | |

| Anti-Compressive Strength | (N/m²) | ≥6.9*108 | ≥6.9*108 | ≥6.9*108 | ≥6.9*108 | ≥6.9*108 | ≥6.9*108 | ≥6.9*108 | ≥6.9*108 | ≥6.9*108 | ≥6.9*108 | ≥6.9*108 | ≥6.9*108 | ≥6.9*108 | ≥6.9*108 | ≥6.9*108 |

| [kgf/mm²] | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 | |

| Anti-Tensile Strength | (N/m²) | (0.2~0.5)*108 | (0.2~0.5)*108 | (0.2~0.5)*108 | (0.2~0.5)*108 | (0.2~0.5)*108 | (0.2~0.5)*108 | (0.2~0.5)*108 | (0.2~0.5)*108 | (0.2~0.5)*108 | (0.2~0.5)*108 | (0.2~0.5)*108 | (0.2~0.5)*108 | (0.2~0.5)*108 | (0.2~0.5)*108 | (0.2~0.5)*108 |

| [kgf/mm²] | 2~5 | 2~5 | 2~5 | 2~5 | 2~5 | 2~5 | 2~5 | 2~5 | 2~5 | 2~5 | 2~5 | 2~5 | 2~5 | 2~5 | 2~5 | |

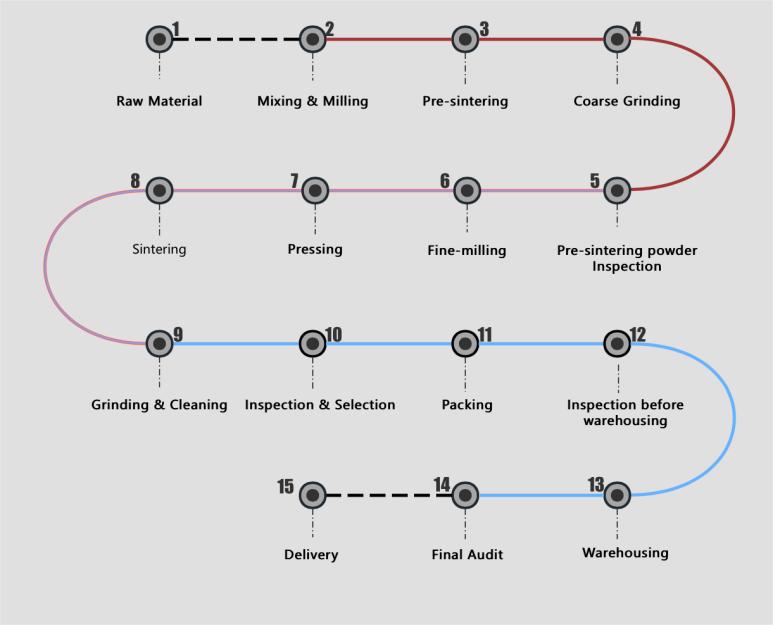

Process Flow