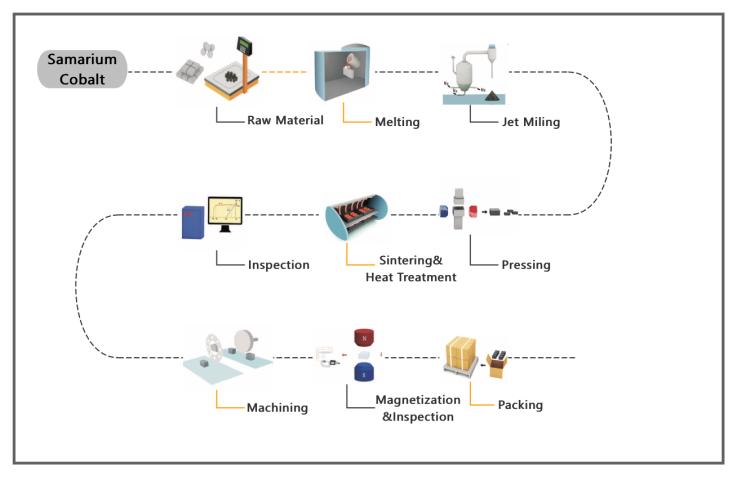

Samarium-cobalt magnet is a kind of rare earth permanent magnet material with high temperature resistance, excellent thermal stability and high coercivity. The main raw materials of samarium-cobalt magnet are samarium and cobalt.The samarium-cobalt magnet with a certain shape is produced by furnace. powder manufacturing, pressing molding, sintering and precisely machining. Although the room temperature magnetic property of samarium-cobalt magnet is inferior to that of NdFeB magnet, its thermal stability is more than10 times that of NdFeB magnet. When the temperature exceeds 150C, the magnetic energy product, coercivity and thermal stability of samarium cobalt magnet all exceed that of NdFeB magnet. Samarium cobalt is the best permanent magnetic material with excellent thermal stability at present.

| ∇ Low Cost |

| ∇ Strong Corrosion Resistance |

| ∇ Temperature range between 250°C and 550°C |

| ∇ Strong Demagnetization Resistance |

|

∇ High Corrosion Resistance; Highly resistant to oxidation |

Typical Physical Properties of Samarium Cobalt Materials

| Physical Characteristics | unit | SmCo5 | Sm2Co17 | |

| Density | g/cm3 | 8.1 - 8.6 | 8.2-8.5 | |

| Tc | °C | 750 | 850 | |

| Bending Strength | MPa | 120 - 180 | 80 - 160 | |

| Compressive Strength | MPa | 1000 - 1200 | 800 - 1200 | |

| Tensile Strength | MPa | 40 | 35 | |

| Fracture Toughness | MPa • m1/2 | 1 - 2 | 1.5 - 2.5 | |

| Modulus of Elasticity | MPa | 1.3 x 105 | 2 x 105 | |

| Modulus of Rigidity | MPa | / | 8 x 104 | |

| Poisson Ratio | / | / | 0.2 | |

| HV | / | 400 - 500 | 500 - 650 | |

| Resistivity | µΩ • cm | 0.5 - 0.6 | 0.8 - 0.9 | |

| Thermal Conductivity | W • (m •°C)-1 | 11 | 10 | |

| Specific Heat | kJ (kg •°C)-1 | 0.37 | 0.35 | |

| Thermal Expansion Coefficient | Lcaxis | x10-6 K | 7 | 8 |

| Llc axis | 15 | 11 | ||

Magnetic Properties

1 T = 10 kGs = 10000 Gs ; 1 kOe = 79.6 kA/m ; 1 MGOe = 7.96 kJ/m3

| Material | Grade | Br Remanence | Hcb Coercivity | Hcj Intrinsic Coercivity | (BH) Maximum Energy Product | Tw | α (Br) (20°C - 150°C) |

| kGs | kOe | kOe | MGOe | °C | %/°C | ||

| SmCo5 | XG6 | 5.0 - 5.8 | 4.7 - 5.7 | >20 | 6 - 8 | 250 | -0.04 |

| XG8 | 5.8 - 6.5 | 5.4 - 6.4 | >20 | 8 - 10 | |||

| XG10 | 6.4 - 7.2 | 6.0 - 7.1 | >20 | 10 - 12 | |||

| XG12 | 7.0 - 7.6 | 6.5 - 7.4 | >20 | 12 - 14 | |||

| XG14 | 7.5 - 8.2 | 7.0 - 8.0 | >20 | 14 - 16 | |||

| XG16 | 7.7 - 8.6 | 7.2 - 8.4 | >20 | 15 - 18 | |||

| XG18 | 8.2 - 9.0 | 7.8 - 8.8 | >20 | 16 - 20 | |||

| XG20 | 8.6 - 9.2 | 8.2 - 9.0 | >20 | 18 - 21 | |||

| XG22 | 9.0 - 9.5 | 8.5 - 9.3 | >20 | 20 - 23 | |||

| XG24 | 9.5 - 9.8 | 8.6 - 9.2 | >20 | 22 - 24 | |||

| XG26 | >9.8 | >9.0 | >18 | 24 - 26 | |||

| Sm2Co17 | XGS6 | 5.0 - 5.8 | 4.5 - 5.7 | >18 | 6 - 8 | 350 | - 0.035 |

| XGS8 | 5.8 - 6.5 | 5.4 - 6.4 | >18 | 8 - 10 | |||

| XGS10 | 6.4 - 7.2 | 6.0 - 7.1 | >18 | 10 - 12 | |||

| XGS12 | 7.0 - 7.6 | 6.5 - 7.4 | >18 | 12 - 14 | |||

| XGS14 | 7.5 - 8.2 | 7.0 - 8.0 | >18 | 14 - 16 | |||

| XGS16 | 7.7 - 8.6 | 7.2 - 8.4 | >18 | 15 - 18 | |||

| XGS18 | 8.2 - 9.0 | 7.8 - 8.8 | >18 | 16 - 20 | |||

| XGS20L | 8.6 - 9.4 | 4.5 - 9.2 | 5 - 18 | 18 - 22 | |||

| XGS20 | 8.6 - 9.4 | 7.8 - 9.2 | 18 - 25 | 18 - 22 | |||

| XGS20H | 8.6 - 9.4 | 7.8 - 9.2 | >25 | 18 - 22 | |||

| XGS22L | 9.0 - 9.7 | 4.5 - 9.0 | 5 - 18 | 20 - 24 | |||

| XGS22 | 9.0 - 9.7 | 8.3 - 9.5 | 18 - 25 | 20 - 24 | |||

| XGS22H | 9.0 - 9.7 | 8.3 - 9.5 | >25 | 20 - 24 | |||

| XGS24L | 9.5 - 10.0 | 4.5 - 9.5 | 5 - 18 | 22 - 26 | |||

| XGS24 | 9.5 - 10.0 | 8.6 - 9.7 | 18 - 25 | 22 - 26 | |||

| XGS24H | 9.5 - 10.0 | 8.6 - 9.7 | >25 | 22 - 26 | |||

| XGS26L | 10.0 - 10.4 | 4.5 - 10.0 | 5 - 18 | 24 - 27 | |||

| XGS26 | 10.0 - 10.4 | 9.0 - 10.1 | 18 - 25 | 24 - 27 | |||

| XGS26H | 10.0 - 10.4 | 9.0 - 10.1 | >25 | 24 - 27 | |||

| XGS28L | 10.4 - 10.8 | 4.5 - 10.1 | 5 - 18 | 26 - 28 | |||

| XGS28 | 10.4 - 10.8 | 9.5 - 10.5 | 18 - 25 | 26 - 28 | |||

| XGS28H | 10.4 - 10.8 | 9.5 - 10.5 | >25 | 26 - 28 | |||

| XGS30L | 10.8 - 11.1 | 4.5 - 10.5 | 5 - 18 | 28 - 30 | |||

| XGS30 | 10.8 - 11.1 | 9.8 - 10.8 | 18 - 25 | 28 - 30 | |||

| XGS30H | 10.8 - 11.1 | 9.8 - 10.8 | >25 | 28 - 30 | |||

| XGS32L | 11.1 - 11.4 | 4.5 - 10.8 | 5 - 18 | 30 - 32 | |||

| XGS32 | 11.1 - 11.4 | 10.1 - 11.0 | 18 - 25 | 30 - 32 | |||

| XGS32H | 11.1 - 11.4 | 10.1 - 11.0 | >25 | 30 - 32 | |||

| XGS33L | 11.3 - 11.5 | 4.5 - 11.0 | 5 - 18 | 31 - 33 | |||

| XGS33 | 11.3 - 11.5 | 10.4 - 11.2 | 18 - 25 | 31 - 33 | |||

| XGS33H | 11.3 - 11.5 | 10.4 - 11.2 | >25 | 31 - 33 | |||

| XGS34L | 11.4 - 11.7 | 4.0 - 11.0 | 5 - 18 | 32 - 34 | |||

| XGS34 | 11.4 - 11.7 | 10.4 - 11.4 | 18 - 25 | 32 - 34 | |||

| XGS34H | 11.4 - 11.7 | 10.4 - 11.4 | >25 | 32 - 34 | |||

| XGS35L | 11.6 - 11.9 | 4.5 - 11.2 | 5 - 18 | 33 - 35 | |||

| XGS35 | 11.6 - 11.9 | 10.6 - 11.5 | 18 - 25 | 33 - 35 | |||

| XGS35H | 11.6 - 11.9 | 10.6 - 11.5 | >25 | 33 - 35 | |||

| XGS36L | 11.8 - 12.3 | 4.5 - 11.5 | 5 - 18 | 34 - 36 | |||

| XGS36 | 11.8 - 12.3 | 10.9 - 11.6 | 18 - 25 | 34 - 36 | |||

| XGS36H | 11.8 - 12.3 | 10.9 - 11.6 | >25 | 34 - 36 | |||

| Low Temperature Coeff. Sm2Co17 | XGS16LT | 7.7 - 8.2 | 6.8 - 7.6 | >20 | 14 -16 | 350 | ±0.005 |

| XGS18LT | 8.2 - 8.6 | 7.4 - 8.2 | >20 | 16 - 18 | |||

| XGS20LT | 8.6 - 9.2 | 8.6 - 9.2 | >20 | 18 - 20 | |||

| XGS22LT | 9.2 - 9.7 | 9.2 - 9.7 | >20 | 20 - 22 | -0.005 | ||

| XGS24LT | >9.5 | >8.7 | >20 | 22 - 24 | |||

| High Temperature Resistance Sm2Co17 | XGS20HT | 8.6 - 9.2 | 7.8 - 8.8 | >25 | 18 - 20 | 550 | -0.06 |

| XGS22HT | 9.2 - 9.7 | 8.2 - 9.2 | >25 | 20 - 22 | |||

| XGS24HT | 9.5 - 10 | 8.6 - 9.7 | >25 | 22 - 24 | |||

| XGS26HT | >10.0 | >9.0 | >25 | 24 - 27 |

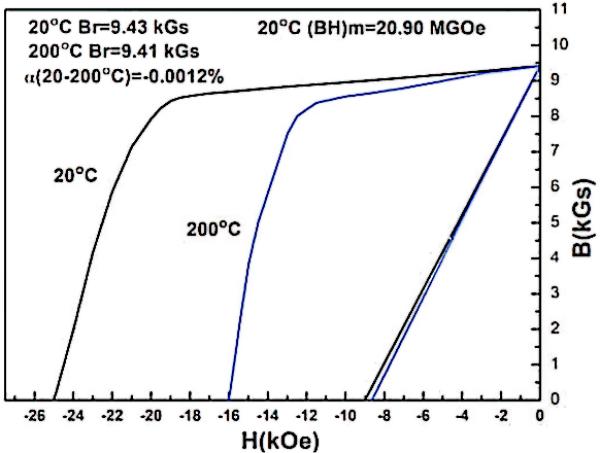

Low Temp. Coeff. Magnets

Features: Within a certain temperature range, Br of SmCo does not change with temperature. Low temperature coefficient magnets can generally be used in various precision instruments, gyroscopes and automatic driving etc. Our company can prepare zero temperature coefficient and positive temperature coefficient magnets.

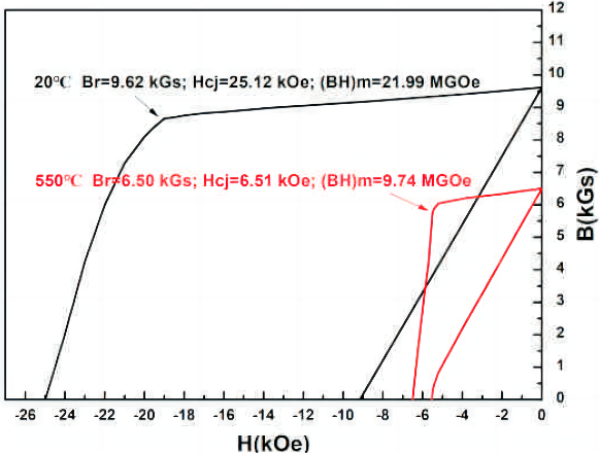

High Temperature Resistant Magnets

Features: Magnets can be used at more than 550℃. The coercivity of high temperature resistant magnet prepared by our company at 550°C is still 6.51 kOe, and the magnetic loss at high temperature is less than 5%.

Process Flow