Sintered neodymium magnets are the world’s most powerful commercially available magnets, with energy products ranging from 33 to 52 MGOe. They offer an ideal solution for applications requiring strong, highly coercive magnets available in large quantities at a relatively low cost. Sintered neodymium magnets are widely used in consumer products like cell phones, speakers, fasteners, and toys, as well as in industrial applications such as metal detectors, oil filters, alternators, flow meters, and welding clamps. They are also essential in MRI machines, hybrid and electric vehicles, and wind turbines due to their high power and compact size. Sintered neodymium magnets come in various shapes—blocks, rings, arcs, discs, spheres, and more—with Ni-Cu-Ni plating being the most common coating, although other finishes are also available.

|

∇ Most powerful permanent magnets |

| ∇ High performance at a low cost |

| ∇ Excellent Demagnetization Resistance |

| ∇ Options for standard and high-temperature materials |

| ∇ Energy products exceeding 50 MGOe |

Magnetic Properties of Sintered neodymium magnets

| Grade | Br | HcB | Hcj | (BH) max | Recommend Maximum Working Temp | ||||||||

| kGs | T | kOe | kA/m | kOe | kA/m | MGOe | kJ/m³ | L/D≥0.7 | |||||

| Max | Min | Max | Min | Min | Min | Min | Min | Max | Min | Max | Min | °C | |

| N30 | 11.2 | 10.8 | 1.12 | 1.08 | ≥10 | ≥796 | ≥12 | ≥955 | 31 | 28 | 247 | 223 | ≤80 |

| N33 | 11.7 | 11.3 | 1.17 | 1.13 | ≥10.5 | ≥836 | ≥12 | ≥955 | 34 | 31 | 271 | 247 | ≤80 |

| N35 | 12.1 | 11.7 | 1.21 | 1.17 | ≥10.9 | ≥868 | ≥12 | ≥955 | 36 | 33 | 287 | 263 | ≤80 |

| N38 | 12.6 | 12.2 | 1.26 | 1.22 | ≥11.3 | ≥899 | ≥12 | ≥955 | 39 | 36 | 311 | 287 | ≤80 |

| N40 | 12.9 | 12.6 | 1.29 | 1.26 | ≥11.6 | ≥923 | ≥12 | ≥955 | 41 | 38 | 327 | 302 | ≤80 |

| N42 | 13.2 | 12.9 | 1.32 | 1.29 | ≥12 | ≥955 | ≥12 | ≥955 | 43 | 40 | 342 | 318 | ≤80 |

| N45 | 13.7 | 13.3 | 1.37 | 1.33 | ≥12.5 | ≥955 | ≥12 | ≥955 | 46 | 43 | 366 | 342 | ≤80 |

| N48 | 14.0 | 13.7 | 1.40 | 1.37 | ≥12.9 | ≥1027 | ≥12 | ≥955 | 49 | 46 | 390 | 366 | ≤80 |

| N50 | 14.3 | 14.0 | 1.43 | 1.40 | ≥13.1 | ≥1043 | ≥12 | ≥955 | 51 | 48 | 406 | 382 | ≤80 |

| N52 | 14.5 | 14.3 | 1.45 | 1.43 | ≥13.3 | ≥1138 | ≥11 | ≥876 | 53 | 50 | 422 | 398 | ≤70 |

| N54 | 14.6 | 14.4 | 1.46 | 1.44 | ≥13.6 | ≥1150 | ≥11 | ≥876 | 55 | 52 | 438 | 414 | ≤70 |

| N56 | 14.8 | 14.6 | 1.48 | 1.46 | ≥13.7 | ≥1160 | ≥11 | ≥876 | 57 | 54 | 454 | 430 | ≤70 |

| 30M | 11.2 | 10.8 | 1.12 | 1.08 | ≥10.9 | ≥868 | ≥14 | ≥1114 | 31 | 28 | 247 | 223 | ≤100 |

| 33M | 11.7 | 11.3 | 1.17 | 1.13 | ≥10.5 | ≥836 | ≥14 | ≥1114 | 34 | 31 | 271 | 247 | ≤100 |

| 35M | 12.1 | 11.7 | 1.21 | 1.17 | ≥10.9 | ≥868 | ≥14 | ≥1114 | 36 | 33 | 287 | 263 | ≤100 |

| 38M | 12.6 | 12.2 | 1.26 | 1.22 | ≥11.3 | ≥899 | ≥14 | ≥1114 | 39 | 36 | 311 | 287 | ≤100 |

| 40M | 12.9 | 12.6 | 1.29 | 1.26 | ≥11.6 | ≥923 | ≥14 | ≥1114 | 41 | 38 | 327 | 302 | ≤100 |

| 42M | 13.2 | 12.9 | 1.32 | 1.29 | ≥12.0 | ≥955 | ≥14 | ≥1114 | 43 | 40 | 342 | 318 | ≤100 |

| 45M | 13.7 | 13.3 | 1.37 | 1.33 | ≥12.5 | ≥995 | ≥14 | ≥1114 | 46 | 43 | 366 | 342 | ≤100 |

| 48M | 14.0 | 13.7 | 1.40 | 1.37 | ≥12.9 | ≥1027 | ≥14 | ≥1114 | 49 | 46 | 390 | 366 | ≤100 |

| 50M | 14.3 | 14.0 | 1.43 | 1.40 | ≥13.1 | ≥1043 | ≥14 | ≥1114 | 51 | 48 | 406 | 382 | ≤100 |

| 52M | 14.5 | 14.3 | 1.45 | 1.43 | ≥13.3 | ≥1138 | ≥14 | ≥1114 | 53 | 50 | 422 | 398 | ≤100 |

| 54M | 14.6 | 14.4 | 1.46 | 1.44 | ≥13.6 | ≥1150 | ≥14 | ≥1114 | 55 | 52 | 438 | 414 | ≤100 |

| 30H | 11.2 | 10.8 | 1.12 | 1.08 | ≥10 | ≥796 | ≥17 | ≥1353 | 31 | 28 | 247 | 223 | ≤120 |

| 33H | 11.7 | 11.3 | 1.17 | 1.13 | ≥10.5 | ≥836 | ≥17 | ≥1353 | 34 | 31 | 271 | 247 | ≤120 |

| 35H | 12.1 | 11.7 | 1.21 | 1.17 | ≥10.9 | ≥868 | ≥17 | ≥1353 | 36 | 33 | 287 | 263 | ≤120 |

| 38H | 12.6 | 12.2 | 1.26 | 1.22 | ≥11.3 | ≥899 | ≥17 | ≥1353 | 39 | 36 | 311 | 287 | ≤120 |

| 40H | 12.9 | 12.6 | 1.29 | 1.26 | ≥11.6 | ≥923 | ≥17 | ≥1353 | 41 | 38 | 327 | 302 | ≤120 |

| 42H | 13.2 | 12.9 | 1.32 | 1.29 | ≥12.0 | ≥955 | ≥17 | ≥1353 | 43 | 40 | 342 | 318 | ≤120 |

| 45H | 13.7 | 13.3 | 1.37 | 1.33 | ≥12.5 | ≥995 | ≥17 | ≥1353 | 46 | 43 | 366 | 342 | ≤120 |

| 48H | 14.0 | 13.7 | 1.40 | 1.37 | ≥12.9 | ≥1027 | ≥17 | ≥1353 | 49 | 46 | 390 | 366 | ≤120 |

| 50H | 14.3 | 14.0 | 1.43 | 1.40 | ≥13.0 | ≥1034 | ≥17 | ≥1350 | 51 | 48 | 406 | 382 | ≤120 |

| 52H | 14.5 | 14.3 | 1.45 | 1.43 | ≥13.3 | ≥1138 | ≥17 | ≥1350 | 53 | 50 | 422 | 398 | ≤120 |

| 30SH | 11.2 | 10.8 | 1.12 | 1.08 | ≥10.1 | ≥804 | ≥20 | ≥1592 | 31 | 28 | 247 | 223 | ≤150 |

| 33SH | 11.7 | 11.3 | 1.17 | 1.13 | ≥10.6 | ≥844 | ≥20 | ≥1592 | 34 | 31 | 271 | 247 | ≤150 |

| 35SH | 12.1 | 11.7 | 1.21 | 1.17 | ≥11.0 | ≥876 | ≥20 | ≥1592 | 36 | 33 | 287 | 263 | ≤150 |

| 38SH | 12.6 | 12.2 | 1.26 | 1.22 | ≥11.4 | ≥907 | ≥20 | ≥1592 | 39 | 36 | 311 | 287 | ≤150 |

| 40SH | 12.9 | 12.6 | 1.29 | 1.26 | ≥11.6 | ≥939 | ≥20 | ≥1592 | 41 | 38 | 326 | 302 | ≤150 |

| 42SH | 13.2 | 12.9 | 1.32 | 1.29 | ≥12.4 | ≥987 | ≥20 | ≥1592 | 43 | 40 | 342 | 318 | ≤150 |

| 45SH | 13.7 | 13.2 | 1.37 | 1.32 | ≥12.6 | ≥1003 | ≥20 | ≥1592 | 46 | 42 | 366 | 334 | ≤150 |

| 48SH | 14.0 | 13.7 | 1.40 | 1.37 | ≥12.9 | ≥1027 | ≥20 | ≥1592 | 49 | 46 | 390 | 366 | ≤150 |

| 50SH | 14.3 | 14.0 | 1.43 | 1.40 | ≥13.0 | ≥1034 | ≥20 | ≥1592 | 51 | 48 | 406 | 382 | ≤150 |

| 52SH | 14.5 | 14.3 | 1.45 | 1.43 | ≥13.3 | ≥1138 | ≥20 | ≥1592 | 53 | 50 | 422 | 398 | ≤150 |

| 28UH | 10.8 | 10.4 | 1.08 | 1.04 | ≥9.6 | ≥764 | ≥25 | ≥1989 | 29 | 26 | 231 | 207 | ≤180 |

| 30UH | 11.2 | 10.8 | 1.12 | 1.08 | ≥10.1 | ≥804 | ≥25 | ≥1989 | 31 | 28 | 247 | 223 | ≤180 |

| 33UH | 11.7 | 11.3 | 1.17 | 1.13 | ≥10.7 | ≥852 | ≥25 | ≥1989 | 34 | 31 | 271 | 247 | ≤180 |

| 35UH | 12.1 | 11.7 | 1.21 | 1.17 | ≥10.8 | ≥860 | ≥25 | ≥1989 | 36 | 33 | 287 | 263 | ≤180 |

| 38UH | 12.6 | 12.2 | 1.26 | 1.22 | ≥11.3 | ≥899 | ≥25 | ≥1989 | 39 | 36 | 311 | 287 | ≤180 |

| 40UH | 12.9 | 12.6 | 1.29 | 1.26 | ≥11.3 | ≥899 | ≥25 | ≥1989 | 41 | 38 | 326 | 302 | ≤180 |

| 42UH | 13.2 | 12.9 | 1.32 | 1.29 | ≥11.6 | ≥923 | ≥25 | ≥1989 | 43 | 40 | 342 | 318 | ≤180 |

| 45UH | 13.7 | 13.3 | 1.37 | 1.33 | ≥12.5 | ≥995 | ≥25 | ≥1989 | 46 | 43 | 366 | 342 | ≤180 |

| 28EH | 10.8 | 10.3 | 1.08 | 1.03 | ≥9.8 | ≥780 | ≥30 | ≥2388 | 29 | 26 | 231 | 207 | ≤200 |

| 30EH | 11.2 | 10.8 | 1.12 | 1.08 | ≥10.1 | ≥804 | ≥30 | ≥2388 | 31 | 28 | 247 | 223 | ≤200 |

| 33EH | 11.7 | 11.3 | 1.17 | 1.13 | ≥10.3 | ≥820 | ≥30 | ≥2388 | 34 | 31 | 271 | 247 | ≤200 |

| 35EH | 12.1 | 11.7 | 1.21 | 1.17 | ≥10.5 | ≥836 | ≥30 | ≥2388 | 36 | 33 | 287 | 263 | ≤200 |

| 38EH | 12.6 | 12.2 | 1.26 | 1.22 | ≥11.3 | ≥899 | ≥30 | ≥2388 | 39 | 36 | 311 | 287 | ≤200 |

| 40EH | 12.9 | 12.5 | 1.29 | 1.25 | ≥11.3 | ≥899 | ≥30 | ≥2388 | 41 | 38 | 326 | 302 | ≤200 |

| 42EH | 13.3 | 12.8 | 1.33 | 1.28 | ≥11.6 | ≥923 | ≥30 | ≥2388 | 43 | 40 | 342 | 318 | ≤200 |

| 45EH | 13.7 | 13.2 | 1.37 | 1.32 | ≥12.5 | ≥995 | ≥30 | ≥2388 | 46 | 42 | 366 | 334 | ≤200 |

| 28AH | 10.8 | 10.3 | 1.08 | 1.03 | ≥9.6 | ≥764 | ≥35 | ≥2785 | 29 | 26 | 231 | 207 | ≤230 |

| 30AH | 11.2 | 10.8 | 1.12 | 1.08 | ≥9.6 | ≥764 | ≥35 | ≥2785 | 31 | 28 | 247 | 223 | ≤230 |

| 33AH | 11.7 | 11.3 | 1.17 | 1.13 | ≥9.6 | ≥764 | ≥35 | ≥2785 | 34 | 31 | 271 | 247 | ≤230 |

| 35AH | 12.1 | 11.7 | 1.21 | 1.17 | ≥9.6 | ≥764 | ≥35 | ≥2785 | 36 | 33 | 287 | 263 | ≤230 |

| 38AH | 12.6 | 12.2 | 1.26 | 1.22 | ≥9.6 | ≥764 | ≥35 | ≥2785 | 39 | 35 | 311 | 278 | ≤230 |

Surface Coating Solution

Note: Corrosion Resistance varies with the shape of the product.

| Coating Material | Thickness | Behaviour | Corrosion Resistance | Remark | ||||

| PCT | Salt Spray | Humidity & Temperature | Acid / Alkaline | Oil | ||||

| Zn (White Zn) | ≥ 5 µm | White | ----- | ♦♦ | ♦♦♦ | ----- | ♦ | |

| Zn (Color Plated ZN) | ≥ 5 µm | Iridescence | ----- | ♦♦♦ | ♦♦♦♦ | ----- | ♦ | |

| Ni+Cu+Ni | ≥ 15 µm | Sliver | ♦♦♦ | ♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦ | ♦♦♦ | |

| Ni+Cu+Ni+Sn | ≥ 15 µm | Sliver | ♦♦♦♦ | ♦♦♦♦ | ♦♦♦♦♦ | ----- | ----- | Excellent performance in welding |

| Chemic Ni | ≥ 5 µm | Sliver | ♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦ | ♦♦♦ | |

| Epoxy | ≥ 12 µm | Black or Grey | ♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦ | Poor wear resistance |

| Passivated | ≤ 2 µm | Black or Grey | ----- | ----- | ♦♦♦ | ----- | ♦♦♦ | |

| Al | ≥ 3 µm | Sliver Grey | ♦♦♦♦ | ♦♦♦ | ♦♦♦♦ | ----- | ♦♦♦ | High performance in glue binding |

| Al+Epoxy | ≥ 15 µm | Black or Grey | ♦♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦♦ | Poor wear resistance |

| Zn+Al | ≥ 10 µm | Sliver or Sliver Grey | ♦♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦♦ | ----- | ♦♦♦♦♦ | |

| Everluber | ≥ 5 µm | Gold | ♦♦♦♦ | ♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦ | |

| Teflon | ≥ 5 µm | Black | ♦♦ | ♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦ | Good wear resistance |

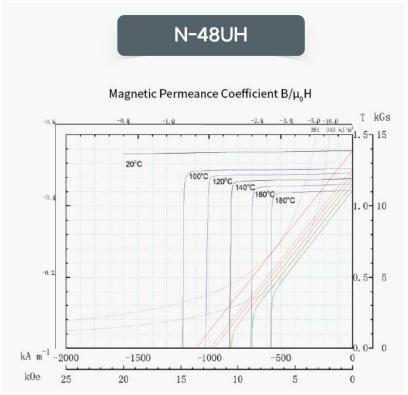

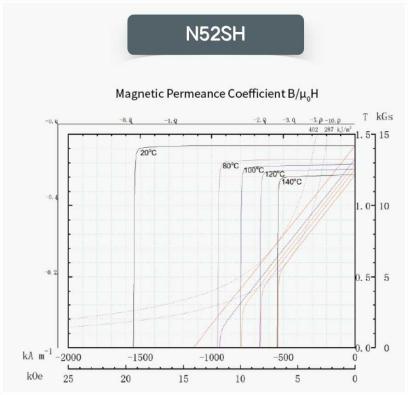

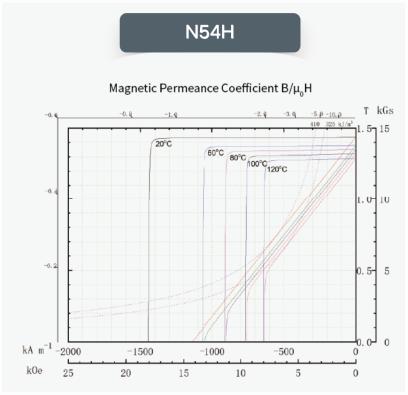

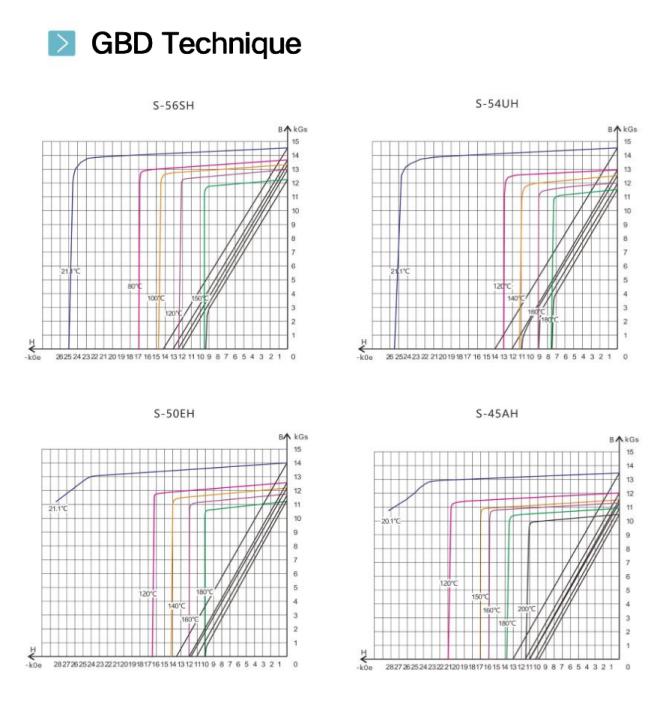

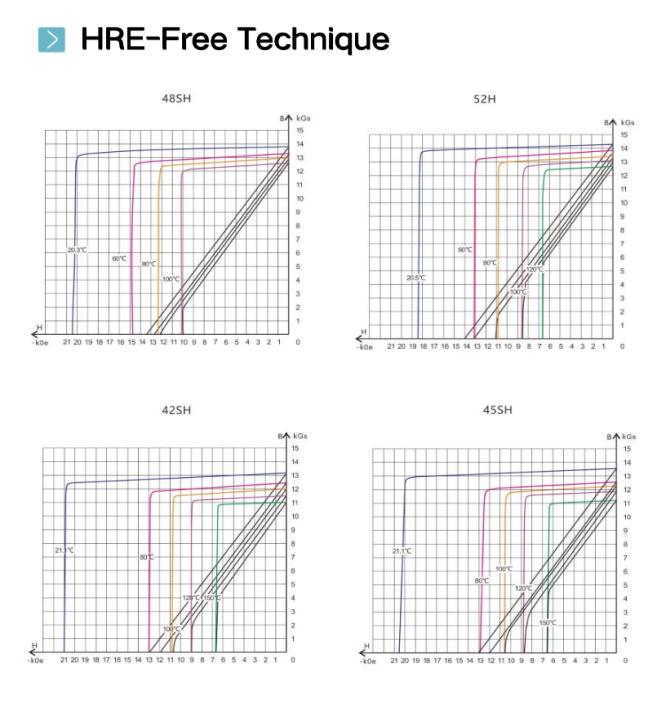

Demagnetization Curve

Process Flow